Section 1 - Introduction

SECTION 1 Introduction

1.1 Model Profile

1.2 Using this Owner's Guide

1.2.1 Hazard Statements

1.2.2 Original Equipment Manufacturer Manuals

1.3 Trojan Owner Questionnaire

1.4 Warranty and Service Information

1.4.1 Trojan Warranty Policy

1.4.2 Warranty Registration

1.4.3 Obtaining Warranty Service

1.4.4 Second owner registration

1.4.5 Hull Identification Number

1.5 Pre-delivery Service

1.6 Owner Registration

SECTION 2 Boating Safety

2.1 Safety and Warning Labels

2.2 Safety Information

2.2.1 Safety Equipment

2.2.2 Power Transmission

2.2.3 Electrical Systems

2.2.4 Fueling and Operating

2.2.5 Electrical System Maintenance

SECTION 3 Profile

3.3.1 Hull

3.3.2 Anti-Fouling Bottom Paint

3.4 Draft

3.6 Underwater Gear

3.6.1 Propellers

3.6.2 Rudder Assembly

3.6.4 Strut Assembly

3.6.4.1 Profile and Layouts

3.6.4.2 Materials

3.6.4.3 Construction

3.6.4.4 Canvas and Upholstery

3.6.4.5 Prop Shaft and Shaft Log Assembly

SECTION 4 DC Electrical System

4.1.1 Battery Selector Switch

4.1.2 Voltmeters

4.1.4 Battery Charger

4.1.5 Inverter

4.2 Circuit Breaker Panels and Equipment

4.2.1 Remote DC Circuit Breaker Panel

4.2.2 Salon DC Circuit Breaker Panel

4.2.3 Design and Purpose

4.3 Powering 12V Equipment

4.4 12 Volt Wiring Standard

4.5 12 Volt Trouble Shooting

4.3 Battery Installation and Maintenance

SECTION 5 AC Electrical System

5.1 Using the AC System

5.1.1 Introduction

5.1.2 Reverse Polarity

5.1.3 Salon AC Panel

5.1.4 Remote AC Panel

5.1.5 Selecting a Power Source

5.1.6 50A Main Breaker

5.1.7 Connecting to Shore Power

5.1.8 Using the Onboard Generator

5.1.9 Dual Dockside Service

5.2.1 Ground Fault Interrupters

5.2.2 Electrical Loads

5.2.3 Salon AC Circuit Breaker Panel

5.2.4 Remote AC Circuit Breaker Panel

5.3 AC Generator

5.4 Air Conditioning System

5.5 Stray Current and Galvanic Corrosion

5.5.1 Stray Current

5.5.2 Galvanic Corrosion

5.6 Bonding System

5.7 AC Trouble Shooting

SECTION 6 Internal Systems

6.1 Fresh Water System

6.1.1 Fresh Water tanks

6.1.2 Fresh Water Hookup

6.1.3 Water Heating System

6.1.4 Shower

6.1.5 Water System Maintenance

6.1.6 Hand Shower

6.17 Fresh Water Washdown

6.1.8 Raw Water Washdown

6.2 Bilge System

6.2.1 Design

6.2.2 Maintenance

6.2.3 Garboard Drain

6.2.4 Bilge Pumps

6.3 Sanitation System

6.3.1 Waste Holding Tank

6.3.2 Heads

6.3.3 Winterization

6.4 Optional Sanitation Systems

6.4.1 Grey Water System

6.4.2 Overboard Discharge

6.4.3 Direct Overboard Discharge

SECTION 7 Propulsion

7.1 Engine Gauges

7.1.1 Instrument Panel Gauges

7.1.2 Gauge Maintenance

7.2 Controls and Steering

7.2.1 Transmission and Throttle Controls

7.2.2 Steering

7.3 Fuel Systems

7.3.1 Fuel Transfer Pump

7.3.2 FuelTankVents

7.4 Operating Instructions

7.3.3 Fuel Gauges

7.3.4 Gasoline Fuel System

7.3.5 Diesel Fuel System

7.3.6 Halon Fire Suppression System

7.4 Operating Instructions

7.4.1 Fueling

7.4.2 Pre-Start Checklist

7.4.3 Starting the Engines

7.4.4 After Startup

7.4.5 Getting Underway

7.4.6 The Shakedown Cruise

7.5 Trouble Shooting Gauges, Controls and Fuel System

SECTION 8 Maintenance

8.1 General Maintenance Schedule

8.2 Exterior Maintenance

8.2.1 Fiberglass Surfaces

8.2.2 Anti-Fouling Bottom Paint

8.2.3 Caulking and Sealants

8.2.4 Stainless Steel Rails and Hardware

8.2.5 Decorative Striping Tape

8.2.6 Windows

8.2.7 ExteriorVinyl Upholstery

8.2.8 Exterior Carpet

8.2.9 Exterior Painted Surfaces

8.2.10 Exterior Plexiglass

8.3 Interior Maintenance

8.3.1 Interior Woodwork

8.3.2 High Pressure Laminate

8.3.3 Woven Fabrics

8.3.4 Interior Carpet

8.3.5 Interior Fiberglass and Plexiglass

8.4 Mechanical and Electrical System Maintenance

8.4.1 Mechanical System Maintenance

8.4.2 Electrical System Maintenance

8.5 Water, Bilge and Sanitation System Maintenance

8.5.1 Water System Maintenance

8.5.2 Bilge System Maintenance

8.5.3 Sanitation System Maintenance

8.6 Lifting and Winter Storage

8.6.1 Lifting

8.6.2 Winterization

SECTION 9 Miscellaneous

9.1 OEM Suppliers List

OWNER'S GUIDE TO SAFE AND PROPER OPERATION

Sleeping capacity 4std./6opt.

Electrical system 12V DC; 120V AC

Fuel capacity 432 gallons (1635,29 I)

Fresh water capacity 104 gallons (393,68 I)

Waste system capacity 100 gallons (378,54 I)

Length overall 43'11" (13,39 m)

Length overall (w/platform) 44'9" (13,64 m)

Beam (at waterline) 12'2" (3,71 m)

(at gunwale) 15'0" (4,57)

Draft 52" (1,32 m)

Bridge Clearance (w/standard arch) 10'11" (3,33 m)

Freeboard (aft) 3'9" (1,14 m)

(forward) 5'5" (1, 65 m)

Weight (with fuel and water) 32,000 Ibs (14515,2 kg)

Dimensions

Main Cabin ( L x W x H ) 13'1" X 10' x 6'5"

(3,99 x 3,05 x 1,96 m)

Forward Cabin ( L x W x H ) 9'10" X 10' x 6'4"

(2,99 x 3,05 x 1,93 m)

Aft Cabin ( L x W x H ) 7'0 x 6'11" x 6'5"

(2,13 x 2,11 x 1,96 m)

1.2 USING THIS OWNER'S GUIDE

INTRODUCTION

We welcome you to the distinguished family of Trojan Yacht owners. Your Trojan Yacht was conceived with "human engineering" in mind. It was developed for the discriminating yachtsman to use and live in and design through assembly, inspection, and testing has been undertaken with sea worthiness, serviceability, comfort and satisfying eye appeal as major goals.

IT IS IMPORTANT THAT YOU READ AND UNDERSTAND ALL MATERIALS INCLUDED WITH THIS OWNER'S GUIDE PRIOR TO OPERATING YOUR BOAT OR ANY OF ITS EQUIPMENT.

1.2.1

HAZARD STATEMENTS

This guide was prepared and written to serve as an operations manual specifically for your 440 EXPRESS. It includes information on your boat and all its systems.

This guide is organized into ten sections, each dealing with a particular facet of your boat's operation. Detailed drawings and diagrams are also included in this guide

The Trojan Owner's Guide was also developed to enhance your boating safety. Safety precautions and operational tips have been organized in the following manner:

!DANGER!

Substantial property damage if the warning is not observed

!CAUTION!

Property damage if the proper precautions are not observed.

Describes a hazard, which can cause severe injury, death if ignored.

!WARNING!

Describes a hazard that could result in serious personal injury and/or

!CAUTION!

Describes situations that could damage your boat or its components.

NOTE: Various warnings and other important safety information are listed in SECTION 2 of this owner's guide. Please refer to pages 2.1 through 2.4 and review this information prior to operating your boat.

ORIGINAL EQUIPMENT MANUFACTURER (OEM) MANUALS

The second set of manuals that pertain to your new boat are supplied by manufacturers other than Trojan. These manufacturers are referred to as OEM suppliers

Engines, stoves, refrigerators and air conditioners are examples of this type of equipment.

The majority of Trojan's suppliers have created operators and maintenance manuals for their products. This information has been assembled and supplied to you.

Virtually all of your boat's components have their own limited warranty. Warranty registration cards have been provided for those products.

These are your materials. Use a colored highlighter to mark sections of the text that are of special interest. Be sure to supplement your guide with information on wiring or installation of additional equipment that you add to the boat during your period of ownership.

The Trojan Owner's Guide and all component manuals are a permanent part of your boat.

These materials must remain on the vessel during its operation. These materials must also be transferred to the boat's subsequent owners.

Trojan Yachts installed a variety of equipment, which was manufactured by OEM suppliers.

NOTE: Information presented in OEM suppliers literature and manuals takes precedence over information presented in this Owner's Guide. If there is a discrepancy between the Owner's Guide and an OEM supplier's manual, FOLLOW THE INSTRUCTIONS IN THE SUPPLIER'S MANUAL.

Information contained within this Owner's Guide is the most accurate information available at the time of publishing. Trojan reserves the right to change without notice materials, part numbers, specifications or system designs.

1.4 WARRANTY AND SERVICE INFORMATION

1.4.1 TROJAN WARRANTY POLICY. Many of the complex components (engines, generators, stoves, etc

Trojan warrants every boat we manufacture as detailed in the Trojan Limited Warranty

Document. Your copy of the Trojan Limited Warranty appears in Section 1.4 of this guide

Please review this document carefully.

The warranty on your new Trojan is the joint responsibility of the Trojan Yachts, your Trojan Dealer and yourself. All three parties have certain responsibilities to ensure that the warranty remains in force document that is included within this Owner's Guide.

Trojan Dealer Responsibilities:

The Trojan Dealer will review the terms of the warranty and make certain the warranty is registered with Trojan.

Your Trojan Dealer will instruct you on how to obtain warranty service.

The Trojan Dealer will prepare your boat for delivery in accordance with the procedures detailed on the Pre-Delivery Service Record. Your dealer will sign the

Pre-Delivery Service Record and provide you with a copy.

A representative from your Trojan Dealership will conduct a review of how your boat and its systems operate.

The Owners Responsibilities:

Make certain the boat's pre-delivery service record has been completed and mailed to Trojan.

Read and follow all OEM supplied materials. Complete and mail all OEM warranty cards.

Review the Pre-Delivery Service procedure with your dealer Pre-Delivery Service Record. Be certain you sign a copy of the Pre-Delivery Service Record and retain a copy for your records.

At time of delivery, make a complete inspection of the boat and its systems. Document any work that needs to be completed by the dealer in order to met the terms of your agreement.

Read, understand and follow the Trojan Owner's Guide and all materials contained within the Captain's Kit. Contact your dealer if you have any questions. Perform all maintenance in accordance with the operator and service guides. Systems are warranted by their respective manufacturer resolve problems with their products. Your Trojan Dealer can implement these services for the Pre-Delivery Service Record must. Your Trojan Dealership is staffed with knowledgeable professionals who are familiar with your boat and are capable of providing the highest level of service. The Trojan Dealership service personnel will communicate with The Trojan Yachts to ensure you fast and satisfactory solutions to any problem that may arise A "Second Owner Registration Card" has been provided in Section 1.4. The purchaser of Registration of a "pre-owned" Trojan does not extend or in any way modify a boat's original limited warranty. However, purchasers of a pre-owned Trojan can and should register ownership with Trojan. Having this information on file will benefit you should Trojan ever need to contact you.= Signifies that the boat was made by the Trojan Yachts. Every boat manufacturer in= Shows that the boat is a Trojan model 440 EXPRESS. Every different model made= These three positions indicate the boat's hull number. 101 shows that his boat was= This letter denotes the month the hull was molded. "A" signifies January, "8" February= This is the CALENDAR YEAR the boat was made. This boat was made in 1995.= These numbers show the MODEL YEAR of the boat the first one made as a 1996 model.

1.4.4 SECOND OWNER REGISTRATION

A "pre-owned" Trojan should complete this card and submit it to the Trojan Yachts, 1651

Whitfield Ave., Sarasota, FL 34243.

1.4.5 HULL IDENTIFICATION NUMBER (HIN)

The United States Coast Guard has established a universal system of numerically identifying vessels by using a hull identification number or "HIN." This number identifies a boat's make, model, hull number, month, and year of manufacture.

The HIN is found on a boat's transom. Look for it on the starboard side, just below the rub rail or on the transom platform.

Provide your Trojan Dealer with your boat's HIN when contacting them for parts or service.

The HIN consists of 12 alpha or numeric characters.

A typical HIN for a 1995, 440 EXPRESS will read TRJ-EA 1010596.

TRJ the United States has their own three letter designation.

EA by Trojan has its own two digit identifier.

101 the first boat of this model manufactured during this model year. A and so on.

Looking at our HIN example of TRJ-EA 1010596, we see that this boat is a Trojan EXPRESS, is a 1996 model, and that the hull was completed in April 1995. This boat was

1.5 PRE-DELIVERY SERVICE

Your Trojan Dealer will perform a thorough review of your boat and its systems commissioning of the craft. The Trojan Pre-Delivery Service Record serves as a checklist in performing this Pre-Delivery Inspection. Review this completed document with your dealer at the time you take delivery of your boat. Your Trojan Dealer will be happy to explain any of the items or procedures included in the Pre-Delivery Inspection.

The Pre-Delivery Service Record requires the owners signature. Sign this form upon accepting delivery of your new boat. In some cases there may be items that need to be remedied by the dealer after taking delivery. Make a note of these problems and attach a copy to the Pre-Delivery Service Record. This will ensure that these items will be corrected within the terms of the one year limited warranty.

This Pre-Delivery Service Record is a multi-part form. Your dealer will provide you with a copy of this form upon completion of the Pre-Delivery Inspection. Keep your copy of the Pre-Delivery Service Record with your boat's permanent records.

WARRANTY AND SERVICE INFORMATION

REGISTRATION CARDS:

Trojan warrants every boat we manufacture as detailed in the Trojan Limited Warranty Document. Your copy of the Trojan Limited Warranty appears after this page. Please review this document carefully.

The warranty on your new Trojan is the Joint responsibility of Trojan Yachts, your Trojan Dealer and yourself. All three parties have certain responsibilities to ensure that the warranty remains in force. Trojan's responsibilities are outlined in the limited warranty document that is included within this Owner's Guide.

The Trojan Dealer will prepare your boat for delivery in accordance with the procedures detailed on the Pre-Delivery Service Record. This document is found on the preceding pages. The terms of Pre-Delivery include proper registration by completing and signing the service record. Your dealer Pre-Delivery Service Record and provide you with a copy.

This card is a Second Owner Registration Card. The buyer of a previously owned Trojan

can and should register ownership with Trojan.

SECOND OWNER WARRANTY REGISTRATION CARD

Owner's Name:

Would you like to receive future promotional literature from Trojan? Yes No

New owner or selling dealer must complete and mail this registration card to Trojan Yachts

at time of delivery your Trojan Dealer.

(1) year from the date the(2) years from the date the-the first retail purchaser, and five (5) years from the date the product is delivered to the first retail purchaser.limited warranties run concurrently.obligation and the buyer's sole and exclusive remedy against the Manufacturer for breach of express warranty shall be to repair or replace defective parts, free of charge, to the purchaser. These limited warranties are subject to the following terms and conditions: Manufacturer's solenot demanded already. Proper warranty registration is strongly advised. A pre-delivery service record form is furnished with each new boat and is used for the initial warranty registration. This form must be completed by the Authorized Trojan Dealer, signed by the first retail purchaser at the time the boat is delivered and returned to Trojan. A replacement form can be obtained by contacting Trojan at the address indicated below. In order for this Trojan limited warranty to be transferred. subsequent owners must fill out and send to the Manufacturer the Pre-Owned Trojan Ownership Registration Card. or provide to the Manufacturer. in writing. the hull serial number. owner's name and address. date of subsequent purchase. and name of person from whom the boat was purchased.

A division of Carver Boat Corporation

P.O. Box 1010, Pulaski, WI 54162-1010

414-822-3214

WHAT IS COVERED

LIMITED WARRANTY ON NEW TROJAN YACHTS

Trojan Yachts ("Manufacturer") warrants to the first retail purchaser of its boats ("Product") purchased from an authorized Trojan dealer, and properly registered subsequent purchasers, as follows:

1. Should the Product, or any part thereof, be proven to have non-structural defect in material or workmanship, when used under normal operating conditions, Manufacturers will make the non-structural repairs (or, at its sole discretion replace the affected part) for a period of one year after product is delivered to the first retail purchaser, and

2. Should the Product be proven to have blistering of the hull laminate, attributable to water penetration of the gel coat (osmosis), Manufacturer will make repairs for a period of two years. product is delivered to

3. Should the Product be proven to have structural defect in material or workmanship to the hull, when used under normal operating conditions, Manufacturer will make the structural repairs for a period of three years

Product to discover all defects in material or workmanship and notify the Manufacturer or the selling dealer of same. During the warranty period, warranty repairs will be made at the dealer's store or service facility or, at Manufacturer's election, by Manufacturer at its factory, or other location authorized by Manufacturer. Transportation to and from Manufacturer's desilmated repair facility shall be at purchaser's expense. Manufacturer's election to repair the defective Product or replace the defective part is the exclusive remedy and is a condition precedent to any legal or equitable action against Manufacturer. Any action for breach of warranty relating to Product must be brought within a period of sixty (60) days following Manufacturer's failure to repair the Product or replace the defective part.

WHAT IS NOT COVERED

This Warranty does not cover:

1. New Product purchased from any party other than an authorized Trojan dealer. You may verify the authenticity of a dealer by contacting the Manufacturer at (414) 822-3214;

2. Product which has been repaired or altered by persons other than Manufacturer or an authorized Trojan dealer, without written authorization of Manufacturer, or altered in anyway so as to affect its use and operation;

3. Product which has been subjected to accident, negligence, unreasonable use, alteration, tampering, abuse, improper maintenance, mishandling, improper lifting or trailering, or used for racing or commercial purposes, or which has been operated contrary to any printed instructions furnished by the manufacturer;

4. Dealer preparation, cleaning, final adjustments, and alignments, in preparing the Product for delivery or commissioning;

5. Engines, transmissions, outdrives, and other equipment or accessories for which separate warranties are provided by other manufacturers;

6. Window glass and windshield glass breakage;

7. Fit and adjustment of exterior canvas tops, enclosures, and weathercovers;

8. Sacrificial deterioration of anti-fouling paint, or zinc anodes;

9. Equipment not purchased or installed by Manufacturer;

10. Any representation relating to the speed, range, or performance of the Product;

11. Loss of time, loss of use, inconvenience, travel expense, transportation costs, towing, or other matters not specifically covered hereunder;

12. Any act of God.

This warranty gives you specific rights, and you may also have other rights which vary from state to state. This warranty is governed by the laws of the State of Wisconsin. This document contains the entire warranty given by Manufacturer and there are no terms, promises, conditions or warranties other than those contained herein. No oral or written information or advice given by Manufacturer, its dealers, representatives, agents or employees shall create a warranty or in any way increase the scope of this warranty. Manufacturer does not authorize any person to extend the time of this warranty or to create or assume for it any other obligation or liability with respect to its Products. No person. including a dealer. i make any repairs or replacements under this warranty without the prior written a12Proval of Manufacturer. Manufacturer reserves the right to make product improvements through changes in design, material or parts without being obligated to incorporate such changes in Products previously manufactured. This warranty is not transferrable or assignable except as specifically provided below.

THIS EXPRESS WARRANTY IS IN LIEU OF, AND MANUFACTURER DISCLAIMS, ANY AND ALL OTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, WHATSOEVER INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES UNDER THE UNIFORM COMMERCIAL CODE, ANY IMPLIED WARRANTY OF MERCHANTABILITY AND ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY SHALL BE THE SOLE AND EXCLUSIVE REMEDY OF ANY PERSON, WHETHER IN CONTRACT, TORT OR OTHERWISE AND MANUFACTURER SHALL NOT BE LIABLE FOR CONSEQUENTIAL, SPECIAL OR INCIDENTAL DAMAGE, LOST PROFITS, INCONVENIENCE, OR DAMAGE RESULTING FROM A BREACH OF THE EXPRESS OR ANY IMPLIED WARRANTY WHICH IS NOT DISCLAIMED HEREIN NOR FOR ANY OTHER LOSS OR DAMAGE, EXCEPT AS SET FORTH ABOVE.

Some states do not allow limitations on implied warranties, or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. In the event that implied warranties are non-disclaimable, those warranties are disclaimable to the extent permitted by applicable law, and all remaining implied obligations and warranties, are limited in duration to a period of one (1) year or such shorter period as permitted by applicable law.

WARRANTY REGISTRATION

LIMITED WARRANTY

Registration of your boat and its engines is also required by the Federal Safe Boating Act of 1971. Your Trojan Dealer will complete and mail your engine warranty cards as part of the Pre-Delivery Service procedure. Many of the other complex components installed on your boat must also be registered with their respective manufacturer. Warranty cards have been assembled and are contained in the OEM SUPPLIED MATERIALS packet that is part of your Captain's Kit.

ALL WARRANTY CARDS MUST BE COMPLETED AND FORWARDED TO THE APPROPRIATE COMPANY WITHIN 5 DAYS AFTER TAKING DELIVERY OF YOUR TROJAN.

OBTAINING WARRANTY SERVICE

The following requirements must be met before warranty work can be performed on your boat.

1) Your boat must be registered with Trojan Yachts. Registration is accomplished by completing and submitting the Pre-Delivery Service Record to the Trojan Yachts, 1651 Whitfield Ave

2} Pre-Delivery Service must be completed by your Trojan Dealer. See Section 1 information concerning Pre-Delivery Service be signed by both the dealer and the owner. Your Trojan Dealer is the ONLY person authorized to approve warranty work. If warranty service is needed you MUST contact your Trojan Dealer first. There are no exceptions to this policy.

---------------------------------------------------------------

Section 2 - Boating Safety

2.1 Safety and Warning Labels

2.2 Safety Information

2.2.1 Safety Equipment

2.2.2 Power Transmission

2.2.3 Electrical Systems

2.2.4 Fueling and Operating

2.2.5 Electrical System Maintenance

2.3 Engine Exhaust

2.4 Nautical Glossary

2.1 SAFETY AND WARNING LABELS

In addition to the written safety precautions which appear in your Trojan Owner's Guide, these two pages feature safety and warning labels which are affixed throughout your boat. We recommend that you familiarize yourself with these labels and understand the potential hazards that are indicated. The following label is printed on the instrument panel and also affixed to the 110 volt distribution panel.

WARNING: GASOLINE VAPORS CAN EXPLODE BEFORE STARTING ENGINE OR GENERATOR. OPERATE BLOWER FOR 4 MINUTES AND CHECK ENGINE COMPARTMENTS FOR GASOLINE VAPORS. ALWAYS OPERATE BLOWER WHILE GENERATOR IS RUNNING AND BELOW CRUISING SPEED.

DANGER

Do Not use a boarding ladder or swim platform while engines are running or the boat is in motion.

DANGER

This engine compartment is a machinery enclosure. It contains exposed moving parts. Do Not enter this area during equipment operation unless you are a trained service technician.

CAUTION

KEEP CABIN DOOR CLOSED WHEN ENGINES OR GENERATOR ARE RUNNING.

The following label is printed on the instrument panel and also affixed to the 110 volt distribution panel.

(1) THIS APPLIANCE IS DESIGNED FOR USE WITH LPG, LIQUEFIED PETROLEUM GAS ONLY.

(2) Keep cylinder valves closed when boat Is un· attended. Close them Immediately In any emergency. It Is recommended that cylinder valves be closed when appliances are nat in usa.

(3) Be lure appliance valves are closed before openIng cylinder valve.

(4) Be sure to apply IgnlUIII source to burner before opening appliance valve.

(5) Test LPG system as recommended In sign posted In vicinity of LPG cylinder.

NEVER USE FLAME T0 TEST FOR LEAKS.

WARNING: ALWAYS PROVIDE VENTILATION WHEN STOVE IS IN USE TO REPLACE OXYGEN AND TO VENT PRODUCTS OF COMBUSTION. DO NOT USE THIS APPLIANCE FOR COMFORT HEATING.

2.2 SAFETY INFORMATION

Boating safety cannot be overemphasized. The prime prerequisites for boating safety are proper operation of your vessel, knowledge of boating regulations and other "rules of the road," and respect and understanding forthe potential hazards of boating. We strongly recommend that you take full advantage of one ofthe organizations that offer courses, information and other details that deal with all aspects of good seamanship. For your reference, included in this group are:

United States Power Squadrons

P.O. Box 30423

Raleigh, NC 27617

Telephone: 800-243-6000 (toll free)

United States Coast Guard Auxiliary

Contact your local flotilla or

Coast Guard District Headquarters

As the authority and the agency for boating regulations, the U.S. Coast Guard is always available for information and guidance. There are various publications available which deal with safety and various subjects that are or should be of concern to you as a responsible boater.

The sole responsibilityforthe safetyequipmentthatyou own and the procedures that you follow is YOURS. Every Trojan meets or exceeds all applicable NMMA (National Marine Manufacturers Association) and/or United States Coast Guard Regulations in effect on the date of manufacture.

2.2.1 SAFETY EQUIPMENT

I n addition to safety items included as standard equipment on your Trojan, we recommend that you have you r owner's man ual and man uals that cover the eng ines a nd other onboard equipment. Equip your boat to comply with U.S. Coast Guard regulations and also forthe waters in which you will be cruising.

The following is a list of the various warnings and other important information that we feel should be emphasized. Some have already been mentioned in this manual, and we list them here again for emphasis. Some are not of a hazardous nature, but all are important.

WE CAUTION THAT THIS LISTING IS NOT EXHAUSTIVE AND DOES NOT CONSTITUTE ALL OF THE "WARNINGS" OR "CAUTIONS" THAT SHOULD BE RECOGNIZED AND PRACTICED.

2.2.2 POWER TRANSMISSION SYSTEM

Always use the oil recommended in your engine and transmission manual when addition or change of oil is necessary. Failure to do so may result in damage.

Power transmission system - Diesel

It is important that engine supply and return lines are withdrawing and returning to the same tank.

It is very important that no air be allowed to get into the diesel fuel system. Air in the fuel system may result in engine shut-down and it may be necessary to reprime the engine fuel system.

Power transmission system - Exhaust Systems

In the event of "Back-fire" the entire system should be checked to make sure that all hoses and fittings are secure. Cracks in the exhaust system could release deadly carbon monoxide (CO) and water into the boat.

!DANGER!

Engine and generator exhaust systems produce colorless and odorless carbon monoxide gas. Potential prolonged exposure can result in carbon monoxide poisoning which may be harmful or fatal. In order to prevent excessive exposure and reduce the possibility of the accumulation of carbon monoxide in the living areas of the boat, the operator should:

1. Operate engine(s) and/or generator only with an adequate exhaust system (no leaks). To assure this, proper maintenance and periodic inspection, even while operating, are required.

2. Whenever practical and always while underway, keep the cabin entrance door and any portholes or aft hatches closed. This is to avoid the potential for drawing exhaust fumes over the transom and forward into the boat. Provide good air flow through ventilation to enclosed living areas by opening forward windows and/or hatches.

3. Similarly, make sure that fore and aft ventilation is promoted in exterior helm areas that are either partially or fully enclosed.

4. Always have a competent person on watch (awake and alert) and monitoring all living areas for carbon monoxide whenever the engines or generator are in operation.

5. Never allow engines and/or generator to run for prolonged periods while docked or at anchor. Always operate the blowers while idling at slow speeds.

6. Use the carbon monoxide detection device following the instructions that accompany it. Monitor it at least once every hour.

7. At the first sign of an exhaust leak or any carbon monoxide accumulation, immediately evacuate and properly ventilate all enclosed living spaces. Locate the source of the problem and take corrective action.

Similarly, make sure that fore and aft ventilation is promoted in exterior helm areas that are either partially or fully enclosed.

Always have a competent person on watch (awake and alert) and monitoring all living areas for carbon monoxide whenever the engines or generator are in operation.

Never allow engines and/or generator to run for prolonged periods while docked or at anchor. Always operate the blowers while idling at slow speeds.

Use the carbon monoxide detection device following the instructions that accompany it. Monitor it at least once every hour.

At the first sign of an exhaust leak or any carbon monoxide accumulation, immediately evacuate and properly ventilate all enclosed living spaces. Locate the source of the problem and take corrective action.

Similarly, make sure that fore and aft ventilation is promoted in exterior helm areas that are either partially or fully enclosed.

Always have a competent person on watch (awake and alert) and monitoring all living areas for carbon monoxide whenever the engines or generator are in operation.

Never allow engines and/or generator to run for prolonged periods while docked or at anchor. Always operate the blowers while idling at slow speeds.

Use the carbon monoxide detection device following the instructions that accompany it. Monitor it at least once every hour.

At the first sign of an exhaust leak or any carbon monoxide accumulation, immediately evacuate and properly ventilate all enclosed living spaces. Locate the source of the problem and take corrective action.

2.2.3 ELECTRICAL SYSTEMS

Batteries must be handled with caution. They produce explosive gases and corrosive materials. Keep flames and cigarettes away. Ventilate when charging. Always shield eyes when working near batteries.

!CAUTION!

Negative ground system. Reversing the polarity will cause serious damage to the alternator.

Shore power cables

An incorrect shore power connection can result in serious or fatal injury. Disconnect cables and contact a qualified electrician.

Avoid making a connection to a "live" shore outlet, or any unnecessary contact with the cable in wet weather.

The ship-to-shore cables and other A.C. equipment used on your boat are the finest quality and the safest available. The current carried by this equipment can result in serious or fatal injury. Always follow recommended procedures.

!DANGER!

Avoid contact with a live cable, especially in wet weather. Never attempt to connect a live shore outlet in wet weather. Avoid wetting the cable, inputs and all other electrical equipment. Use only 3-wire grounded or double insulated appliances.

Inspect cables, appliance cords and outlets frequently. If worn, have them repaired or replaced immediately. Check specifically for deterioration or overheating. Do not use any electrical equipment that is known or suspected to be defective.

2.2.4 FUELING AND OPERATING

If the odor of gasoline is apparent at any time before or after you are underway, shut down the engines and all electrical systems and investigate the source of odor. Correct the situation before restarting.

Note: Your boat has a lazarette suitable for storage of a one or two man personal watercraft. PWCs operate on gasoline fuel. Therefore the storage space has been sealed from the rest of the hull and provided with separate ventilation. Use caution when storing gasoline in this location. Do not store gasoline elsewhere ie in the yacht.

2.2.5 ELECTRICAL SYSTEM MAINTENANCE

Be sure that all power is off when disconnecting the batteries to prevent sparks when cables are removed. Be sure that there are no gasoline fumes remaining in the bilge. It is advisable to disconnect the batteries prior to draining the fuel lines because you may have spillage.

2.3 CARBON MONOXIDE WARNINGS FOR GASOLINE ENGINES

!DANGER!

Carbon monoxJde (CO) Is a colorless and odorless poisonous gas which Is emitted In engine and generator exhaust. Prolonged exposure to CO can result In unconsciousness, brain damage, and death. In high concentrations, CO can be fatal in minutes; however, the effects of lower concentrations can be just as lethal.

Symptoms of excessive exposure to carbon monoxide are:

• Dizziness • Watering, Itchy eyes

• Drowsiness • Flushed appearance

• Nausea or Vomiting • Inattentiveness

• Headache • Incoherence

• Ringing in the ears • Fatigue

• Throbbing temples • Convulsions

Carbon monoxide accumulation requires Immediate attention! Thoroughly ventilate cabin and cockpit areas. Determine the probable source of the carbon monoxide and correct the condition immediately. Carver has installed CO detectors on your boat. Have these detectors professionally calibrated at regular intervals.

! DANGER!

Persons sleeping onboard can easily be overcome by carbon monoxide without realizing It. Sleeping while the engines or generator are running is NOT recommended. To help preterit carbon monoxide accumulation, ventilate your cabin and cockpit while underway. Open a forward hatch, porthole, or window to allow air to travel through the boats interior.

Have a trained marine technician inspect the boat's exhaust systems whenever the boat is in for service or if you notice a change in the sound of an engine or generator. Maintain proper engine adjustments, condition, and performance.

The following page describes some possible situations where CO may accumulate. 8ecome familiar with these examples and the suggested precautions to help prevent a dangerous accident.

2.4 DEFINITIONS OF TERMS

While reading your Owner's Guide you will encounter many descriptive terms that are unique to seamanship and yachting. The following summary defines these terms as they are used within this

Owner's Guide.

ABAFT -Toward the rear ofthe boat.

ABEAM - At right angles to the boat's keel.

ABOARD -On the boat.

ABREAST - Side-by-side.

ADRIFT - Loose, not on a mooring ortow line.

AFT - Moving toward the stem.

AGROUND - Stuck fast on the bottom.

AHEAD -In a forward motion.

AMIDSHIP -1) An object or area midway between the bow and stern of the boat. 2) An object or area midway between the port and the starboard side of a boat.

AMPERE -The standard unit to measure the strength of an electrical current.

ASTERN -In the back ofthe boat.

BEAM -1) The widest distance across a boat. 2) A transverse structural member that stiffens and supports a portion of the deck.

BILGE - The lowest interior area of a boat's hull, used to collect water that has drained into or entered the vessel.

BILGE PUMP - A pump intended for removal of water that has drained into the boats bilge.

BOW -The front end of a boat.

BOW LI NE - A docking line leading from the boat's bow.

BREAKER - See "circuit breaker".

BRIDGE -The uupper most" steering station from which the vessel is controlled.

-------------------------------------------------------

Section 3 - Profile

3.1 Profile and Layouts

3.2 Materials

3.3 Construction

3.3.1 Hull

3.3.2 Anti-Fouling Bottom Paint

3.4 Draft

3.5 Canvas and Upholstery

3.6 Underwater Gear

3.6.1 Propellors

3.6.2 Rudder Assembly

3.6.3 Prop Shaft and Shaft Log Assembly

3.6.4 Strut Assembly

MODEL PROFILE

3.2 MATERIALS

The hull, deck and shower stalls, are made of molded fiberglass. Many of the fiberglass parts in your boat are further reinforced by laminating core materials between layers of fiberglass.

The exterior or exposed surface of many fiberglass parts is coated with a layer of gel coat. Below the waterline hull surfaces have a layer of vinyl ester under the gel coat.

The exterior walking surfaces of your boat have been textured with non-skid. This provides a solid footing surface on the boat's deck, walkways, ladder steps and swim platforms.

Information on how to maintain the fiberglass surfaces of your boat is included in Section 8.3 of this Owner's Guide.

Several different types of wood are used in your 440 EXPRESS.

Several carefully selected types and thicknesses of premium quality, exterior grade fir plywood are used throughout your boat to construct and reinforce a variety of components. High grade mahogany lumber is used in areas that provide structural strength to the boat and interior framework.

Stainless steel and aluminum are used throughout your 440 EXPRESS These metals provide high strength-to-weight ratios, are non-magnetic, and are highly resistant to moisture.

The safety rails on the 440 EXPRESS are welded from stainless steel rail. Information on how to care for the rails and hardware of your boat can be found in Section 8.3 of this Owner's Guide.

HPL is used within the 440 EXPRESS to surface bulkheads, cabinets and counter tops. These laminates are selected for their strength and durability, are easy to clean, and add colorful highlights to the inside of your boat. Information on cleaning your boat's HPL surfaces will be found in Section 8.4 of this Owner's Guide.

Formed plastic is used in a variety of ways throughout the interior and exterior of your boat. Plastic offers a high strength-to-weight ratio and excellent resistance to the affects of moisture.

A few of the areas where formed plastics are used are in the boats water and sanitation tanks, bridge seat forms, interior mirrors and in electrical circuit breaker panels. Information on cleaning the plastic and acrylic panels is included in Sections 8.3 and 8.4 of this Owner's Guide.

A wide variety of fabrics can be found throughout the interior and exterior of your boat. Woven fabrics are used for interior mattresses and chairs, and vinyl fabrics are used for exterior cushions and helm seats.

The vinyl coating of the interior wall coverings and headliner makes them easy to clean.

The carpet and fabric selected for your boat are of premium grade and have been treated with a popular stain resistant product.

3.3 CONSTRUCTION

3.3.1 HULL

Your 440 EXPRESS was built using a modular construction technique. This method of building boats uses the physical properties of many components to add strength and rigidity to the boat's hull and deck. The interior liners of the boat are securely bonded to the hull and deck to increase strength while minimizing the boat's overall weight.

The hull is made of numerous layers of various types of laminated fiberglass. Its strength is derived from laminating several carefully selected, hand laid layers of fiberglass material that have been impregnated and bonded together with polyester resin. Your hull does not contain any balsa wood coring materials. The actual thickness of your boat's hull varies depending upon the structural requirements of a particular area. The thickness, however, generally increases as you go from the sheer to the keel area of the hull.

I CAUTION I

DO NOT Install an Item Into or through the hull without sealing the area penetrated by the fastener or fitting. Improper or Inadequate sealing may lead to hull leaks or serious hull damage. Consult your TROJAN Dealer for recommendations on what type and brand of sealer to use.

3.3.2 ANTI-FOULING BOTTOM PAINT

The underwater surfaces of your boat are coated with a high quality coat of anti-fouling bottom paint. Trojan uses Rule KL-990 Epoxycop, a tough, abrasion resistant paint for moderately fouling water conditions. The paint has a high copper load and anti-fouling elements that will retard the growth of marine life on the bottom of your boat's hull. The paint's anti-fouling agents have a lifespan of about twelve months. Trojan suggests that you repaint the hull with a fresh coat of bottom paint on an annual basis. To avoid compatibility problems, be sure to use the same brand of paint originally applied to the boat. Failure to do so can void your bottom paint warranty.

To prep the boat for painting, lightly rough up the existing paint with 80 or 100 grit sandpaper. Paint can be applied by brush, roller, or spray. For severely fouling conditions, apply an additional medium to heavy coat of KL-990 Super Epoxycop manufacturer's #K-62 black. For multiple season protection in moderately fouling waters, apply an additional medium to heavy coat of KL-990 Epoxycop (manufacturer's #K-52 black). For both products, if two coats are applied, allow 3-6 hours drying time between coats. KL-990 paints are available through most marine distributors nationwide.

3.3.3 INTERIOR MODULES

Major components and cabin modules are built separate from the hull and deck arid are fitted into the hull before the deck is positioned and secured. Modules are designed to work with the hull and deck to strengthen the boat.

3.3.4 DECK

The deck of the TROJAN 440 EXPRESS uses a complex system of laminated fiberglass to give it the ability to support the superstructure of the boat.

All exterior surfaces, including the non-skid areas are coated with pigmented gelcoat. Where equipment and hardware are fastened, wooden or metal backing plates are used. Many of these backing plates can't be seen on a completed boat because they are actually laminated into the fiberglass. High stress area~ receive additional layers of fiberglass laminates as reinforcement.

The hull and deck are fastened together using the TROJAN ·shoe boxN hull-to-deck joint. This joint creates a strong and highly water tight union between these two critical components of your boat

3.4 DRAFT

A draft of 52" (1,22 m) has been calculated based upon the boat's 28,000 Ib (12 700,80 kg) dry weight. Draft is the depth of water from the water line to the lowest point on the boat, usually the bottom tip of the props.

The draft of a boat will vary depending upon the salinity of the water, the amount of equipment on the boat, the capacity of the fuel, water and waste tanks as well as the number of people on board. Due to these variables, the draft of your boat should be checked when the boat is fully equipped and loaded.

Sheer to Waterline Draft

43" (144,78 cm) 52" ( 121,92 cm)

42" (142,24 cm) 53" ( 124,46 cm)

41" (139,70 cm) 54" (127,00 cm)

40" (137,16 em) 55" ( 129,54 em)

39" (134,62 cm) 56" ( 132,08 em)

Dry weight does not include fuel, water, optional equipment, food, beverages, safety gear or anything else a family is likely to have aboard their boat. The actual weight of your boat will be greater than the dry weight figure listed here.

The approximate weight of your boat can be estimated when the actual draft is known. It will require approximately 2,250 Ibs (1020,60 kg) to increase a 440 EXPRESS's draft by 1" (2,54 cm). If a 440 EXPRESS draws 53" (134,62 cm) at its dry weight of 28,000 Ibs (12700,80 kg), a boat that draws 55" (139,70 cm) will weigh approximately 32,500 Ibs (14742,00 kg).

55"- 53" = 2" X 2,250 Ibs = 4,500 Ibs + 28,000 Ibs = 32,500 Ibs est. total weight

(139,70 cm -134,62 cm = 5,08 cm X 1020,60 kg = 2041,20 kg + 12700,80 kg =

2,54 cm

2,54 cm

14 742,00 kg est. total weight.)

This computation is for estimating purposes only. Use it to generate a rough approximation of your boat's total weight.

The 2,250 Ibs (1020,60 kg) figure used for this draft/weight computation is unique to the shape of the 440 EXPRESS's hull. You can not use this figure on boats other than the 440 EXPRESS.

Excessive weight in the fore or aft sections of the boat will cause a trim change and may yield greater draft than expected. Equip your boat with a good quality depth instrument and allow ample water below the hull while operating.

3.6 UNDERWATER GEAR

3.6.1 PROPELLERS

Your boat is equipped with two propellers. These props are counter-rotating to provide maximum maneuverability and efficiency. Each prop is designated for either right-hand or left-hand rotation.

Propellers come in a wide variety of shapes and sizes to meet the needs of different performance requirements. The actual size and type of propeller used on your boat has been listed on the Pre-Delivery Service Record and the Select Bills of Material found in Section 9.

A basic knowledge of how a propeller works will allow you to better understand the terminology used to describe the aspects of propeller performance.

Diameter - Diameter is twice the distance from the center of the prop shaft to the extreme tips of the propeller blades. Increasing or decreasing the diameter of a prop will have a direct bearing on the RPM that the engines will be capable of developing. This is because changing the blade size changes the amount of blade surface that comes into contact with the water.

Pitch - Pitch is a measure of the helix angle (or angle of attack) of the rotating blade. Pitch can be better understood by imagining the propeller rotating through a semi-solid medium such as butter. The distance (in inches) the propeller will travel in one revolution corresponds to the props pitch. Increasing or decreasing pitch will have a direct bearing on engine RPM. Increasing the props pitch will allow it to take a bigger "bite", increasing the load on the engine and lowering engine RPM.

Prop Slip - A propeller operating in a low viscosity fluid such as water is subject to a certain amount of slip. The difference between a prop's theoretical "bite" and its actual "bite" is referred to as prop slip.

Prop slip is expressed as a percent of the computed theoretical speed. Twenty-five to thirty-five percent slip is quite common for a large boat operating at normal cruising speed.

Changing either the diameter or pitch of a prop will have an effect on engine speed and prop slip. The propellers that Trojan has selected and included with your boat will provide the best overall performance and efficiency under normal conditions and loads. This has been determined by data obtained through on-water testing.

Under normal conditions the engines should turn within the RPM range listed by the engine manufacturer. If the engines exceed this range a change in prop diameter or pitch may be required. Changes to your boat's propellers should only be made by a qualified individual. See your Trojan Dealer before changing or making adjustments to your boat's propellers.

3.6.2 RUDDER ASSEMBLY

Rudders are used to control the direction of the boat while underway. Your boat uses two external rudders. The rudder shafts enter the hull of the boat through a rudder port which is well above the normal waterline. The higher rudder ports and close fitting bearings are enough to keep water from entering the boat. The rudder port system requires no adjustment or maintenance. Rudder movement is controlled through the boat's hydraulic steering system. The boat will turn when water strikes the rudders at an angle. Additional information regarding the steering system can be found in Section 7.2 of this Owner's Guide.

3.6.3 PROPELLER SHAFT AND SHAFT LOG ASSEMBLY

Propeller Shaft - The propeller shaft connects the propeller to the engine output shaft. This shaft is made of a special stainless steel material to exact tolerances. A shaft that is not straight or not in perfect balance will create vibrations that may damage certain propulsion system components.

The propeller shaft MUST be properly aligned between the engine output flange, shaft log and struts in order for it to rotate smoothly. Your Trojan Dealer aligned your boat's propeller shafts as part of the Pre-Delivery Service. We recommend that you have your Trojan Dealer check the shaft alignment after your engines have been run for 25 hours. Alignment must also be checked on an annual basis and/or every time the boat is lifted and launched.

Proper and precise shaft alignment is critical and should be left in the hands of an experienced marine technician.

Once a shaft has been damaged, it is very difficult to repair. Trojan recommends replacing damaged shafts instead of attempting repairs.

Shaft Log - Your boat is equipped with Norscot® propeller shaft seals. Periodically check the tubing connected to the seal. If transmission fluid is not visible in the tube, the seals are not being lubricated. Add ATF Dextron II fluid as necessary.

If a propeller shaft needs to be removed, drain the lubricant by removing the brass drain plug on the bottom of the shaft seal housing. Remove the sight gauge tube from the fittings at the top of the shaft seal housing. Pull the propeller shaft. Loosen the hose clamps and remove the shaft seal assembly.

To reinstall the shaft seals see the re-installation instructions found in the OEM instructions. Contact your dealer if you have any questions regarding the Norscot® propeller shaft seal.

3.6.4 STRUT ASSEMBLY

Struts are fastened to the boat's hull and are used to support the propeller shaft. The

440 use both primary and intermediate struts. Primary struts are the larger aft most

struts. Intermediate struts are installed between the primary strut and the shaft log.

The 440 EXPRESS uses 900 struts. Using 900 struts allows an individual strut to be used on either the port or starboard side of the boat. This makes carrying a spare strut easier and more economical.

A rubber bearing within each strut provides a smooth surface on which the propeller rotates.

------------------------------------------------------------

Section 4 - DC Electrical Systems

SECTION 4 DC Electrical System

4.1 Design and Purpose

4.1.1 Battery Selector Switch

4.1.2 Voltmeters

4.1.3 Powering 12V Equipment

4.1.4 Battery Charger

4.1.5 Inverter

4.2 Circuit Breaker Panels and Equipment

4.2.1 Remote DC Circuit Breaker Panel

4.2.2 Salon DC

4.3 Battery Installation and Maintenance

4.4 12 Volt Wiring Standard

4.5 12 Volt Trouble Shooting

4.1 DESIGN AND PURPOSE

Your TROJAN 440 EXPRESS is equipped with a 12 Volt DC

Wire-runs and connections are positioned to prevent abrasion and exposure to moisture, as well as to remain accessible for inspection, repairs and addition of electrical components. Electrical wire used throughout your boat is plastic coated, color-coded wire. A guide to the color code system used by Trojan can be found in Section 4.4. Connections are made using crimped connector points.

Your boat's electrical system is virtually maintenance free, with only the batteries requiring periodic inspection and maintenance.

4.1.1 BATTERY SELECTOR SWITCH

The Direct Current electrical system is powered by two heavy duty D8 batteries. The batteries are firmly anchored outboard of the port engine. Refer to Section 8.4 for battery maintenance.

The power within these batteries is controlled by the battery selector switch which is located below the helm seat on the cockpit panel. The battery selector switch acts as a master disconnect as well as a selector switch for either the STARBOARD battery, the PORT battery, or both batteries together.

With your battery selector switch in the OFF position, all 12V power is disconnected from all equipment except the bilge pumps and voltmeters. When the switch is in the BOTH position, the electrical power is being supplied by both batteries.

Use both batteries to start your engines when both batteries have a charge of less than 11 volts. This is the only time you should use the BOTH position. Start one engine with the selector in the BOTH position, when the engine is running smoothly, switch to STARBOARD or PORT and start the other engine. The engine which is running will generate enough charge to start the other engine.

Alternating the use of your two batteries will prolong their life.

The 440 EXPRESS is equipped with a momentary starting parallel system which connects both port and starboard batteries thru a momentary solenoid while cranking. The port and Starboard engine disconnects are located in the engine compartment. These switches disconnect all of the engine's electrical systems only.

! CAUTION!

NEVER turn the battery selector switch to the "OFF" position while an engine or engines are running. Doing this will damage the alternator or engine wiring.

4.1.2 VOLTMETERS

When Starting Your Engines

! DANGER!

Read, understand and follow the procedures described in Section 7.3 of this

Owner's Guide before starting your boat's engines. Improper starting procedures can create hazardous situations.

! CAUTION!

TURN OFF all electronic communication and navigation equipment PRIOR TO starting the boat's engines. The large swing in the current supply during engine start-up can damage electronic equipment.

1) Activate the voltmeter by making sure the circuit breakers marked VOLTMETER are in the ON position. These breakers are located on the battery selector switch panel.

2) The voltmeter is installed on the main load panel above the salon lounge aft. Look at the voltmeter to determine which battery has the LOWEST available voltage. The voltmeter is activated by the switch that is installed immediately below the voltmeter.

Toggle the voltmeter switch to PORT or STARBOARD.

3) If your voltmeter shows that one battery has a lower level of charge than the other, switch the battery selector switch to the battery that has the HIGHEST available voltage.

4) Start one of the boat's engines. When it is idling smoothly, start the remaining engine. Start each engine independently. Never try to start both engines at once.

5) After the engines are running, switch the selector switch to the battery bank that had the LOWEST voltage reading. This will allow the engine's alternator to recharge the low battery. Refer to 4.1.1 for information on operating the battery selector switch.

The voltmeter reads static voltage-when the engines are off. When the engines are running, one battery will indicate a higher reading than the other. This is because the voltmeter reads alternator charging rate when the engines are running. The position of the battery selector switch determines which battery will be charged by the alternator.

4.1.3 POWERING 12V EQUIPMENT

Using the DC electrical system requires thoughtful power management practices. Even with the engines running, it is possible to use all the power the alternators generate. Do not operate lights or other DC loads unnecessarily. Check the power usage periodically, especially if the engines are not running.

Without an engine running, a battery will discharge as it powers 12 volt equipment. Operating 12 volt equipment without charging a battery will eventually completely discharge the battery. Using only one battery at a time will allow you to totally discharge that battery and keep the other battery in reserve to start the engines.

Fully charged batteries that have not been charged or discharged for at least 2 hours should indicate between 12.3 to 12.6 volts. A reading below this level indicates a partly discharged battery.

4.1.4 BATTERY CHARGER

Your 440 EXPRESS is equipped with an 80 Amp battery charger. The battery charger uses AC power to recharge the 12 volt batteries. The battery charger is installed on the engine compartment's forward and starboard bulkhead.

Provide AC power to the battery charger by turning the AC breaker labeled BATTERY CHARGER on the cockpit panel to the "ON" position.

When activated, the battery charger automatically monitors the charge of both engine and generator batteries, regardless of the position of the battery selector switch. When the voltage in a battery drops below a predetermined level, the charger automatically recharges the low battery.

The battery charger will charge the batteries even when the battery selector switch is in the OFF position or engine battery switches are off.

More information on using the battery charger can be found in Section 5.2.3 of this owner's guide.

4.1.5 INVERTER

Your boat is equipped with an inverter which converts 12Volt DC to 110Volt AC making it possible to operate the VCR and the television. The electrical system automatically connects the inverter to the television and stereo if the dockside wiring is not hooked up or the generator is not running. Be aware that this equipment exerts a "load" on a 12Volt electrical system when used without the engines running.

4.2 CIRCUIT BREAKER PANELS & EQUIPMENT

The12 volt Circuit Breaker Panel manages 12 volt electrical power. The 12 volt service is split between two circuit breaker panels, a remote panel below the helm seat and the main DC load center panel on the aft starboard bulkhead of the boat's salon.

At regular intervals, test the batteries' voltage by activating the test switch below the voltmeter on the salon breaker panel. This connects each battery separately to the voltmeter. Fully charged batteries should indicate between 12.3 and 12.6 volts. A reading below this level indicates a partially discharged battery.

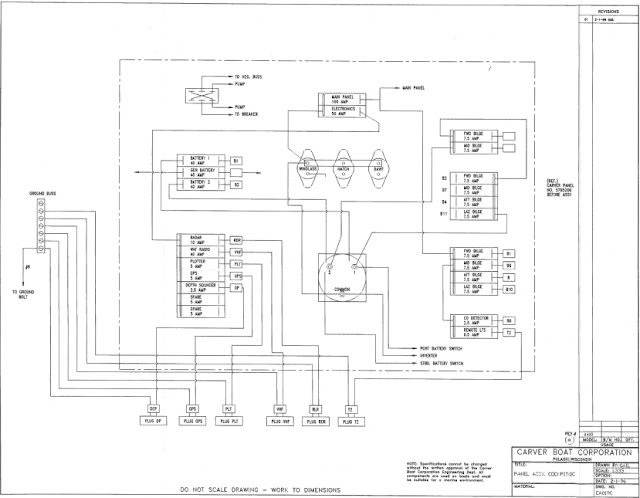

4.2.1 MAIN DC LOAD CENTER

A drawing illustrating the 12 volt circuit breaker panel in the salon appears on page 8 in this section of the Owner's Guide.

MAIN circuit group (bottom, middle)

MAIN: The 100 amp MAIN circuit breaker must be in the "ON" position in order for any other 12 volt circuit breakers to function. When leaving the boat, it is recommended that the MAIN switch be turned off. This will prevent draining the battery if any accessories were inadvertently left on. It also disconnects the ignition/start switches.

NOTE: Turning this switch off will not affect the automatic operation of the electric bilge pumps, voltmeters, battery charger or CO monitors.

SPARE: The 20 amp spare circuit breaker has been added for owner installed equipment.

LIGHTS circuit group (middle, port) - Labeled as follows:

NAV LIGHTS: Power to the navigation lights on the 440 EXPRESS is controlled by this 10 amp breaker. A switch at the helm turns the lights on or off.

PANEL LIGHTS: A switch at the helm control station turns the panel lights on and off. Power to the panel lights is controlled by this 7.5 amp breaker.

ENG/RM EXT: The 15 amp breaker controls power to the engine room lights. These are manually switched on and off at the helm station.

FWD STATEROOM L TS: This 15 amp breaker controls power to the master stateroom lights. The lights can be turned on and off by a switch on the inboard side of the vanity.

GALLEY SLN/L TS: The 20 amp breaker controls power to the lights in the galley and salon area. The lights can be turned on and off by using the switches located in the galley or salon.

AFT ST RM HEAD LIGHTS: Power to the interior lights in the boat's aft cabin is controlled by this 10 amp breaker. The lights can be turned on and off by using the switches in the aft stateroom.

SPOTLIGHT: The spotlight can be operated at the boat's helm station. Power to the spotlight is controlled by this 10 amp breaker.

PROPULSION circuit group (bottom, forward) - Labeled as follows

PORT IGN and STBD IGN: These two 20 amp breakers control the engines' ignition circuits. In addition to the 12 volt MAIN and the battery selector switch, these breakers must be turned on prior to starting the engines.

ACCESSORIES circuit group (top)

HALON: A SEA-FIRE automatic Halon fire suppression system has been installed on the 440 EXPRESS. Power to this system is controlled by this 2.5 amp breaker labeled HALON. Refer to the SEA-FIRE operation manual for more information.

WASTE MONITOR: This 2.5 amp breaker supplies power to the waste monitor circuit. A gauge located in the vanity cabinet of the forward head indicates the amount of waste in the forward holding tank. A similar gauge is in the forward end of the aft head vanity cabinet which indicates the waste in the aft holding tank.

WATER MONITOR: This 2.5 amp breaker controls a sensor that monitors the volume of fresh water in the boat's water storage tanks. A gauge located in the port helm instrument panel indicates the average volume of the two tanks.

STEREO: This 10 amp breaker controls power to the boat's stereo. The standard stereo system is an AM/FM cassette with six speakers, two in the salon, two in the forward stateroom and two in the radar arch. Two stereo options are available. Option #1 adds a CD changer, a cockpit amplifier, a sub-woofer in the cockpit and two speakers in the cockpit behind the windshield. Option #2 adds two speakers in the aft stateroom and an amplifier and subwoofer with two BOSE speakers in the salon. These additional systems are powered via signals from the stereo low level outputs and have separate low level volume controls near the stereo.

REFER: The 440 EXPRESS is equipped with a refrigerator that can be powered by either DC or AC power. Power to the refrigerator for DC operation is controlled by the 15 amp breaker. Consult the operator's manual supplied by the manufacturer of the refrigerator for more information.

HORN: This 15 amp breaker controls power to the boat's horn. Activating a switch at the helm station will sound the horn.

HELM ACCESSORIES: This 10 amp breaker controls power for additional dealer or owner installed accessories at the helm.

CABLE MASTER 1: This 20 amp breaker controls the optional shore cable feed and retrieve circuit for the main AC power inlet.

TRIM TABS: This 20 amp breaker controls power to boat's trim tabs. Refer to Section 7.4 OPERATING INSTRUCTIONS for more information on using trim tabs.

FWD HEAD: Power to the Vac-U-Flush electric head is supplied through the 10 amp breaker. More information on operating and servicing your boat's electric head can be found in the operator's manual supplied by the manufacturer.

AFT HEAD: Power to the Vac-U-Flush electric head is supplied through this 10a breaker. More information on operating and servicing your boat's electric head can be found in the operator's manual supplied by the manufacturer.

VENT MOTOR: This 10 amp breaker controls power to the vent motor in the forward windshield area.

CABLE MASTER 2: This 20 amp breaker controls the optional shore cable feed and retrieve circuit for the air conditioning service.

PUMPS circuit group (middle. aft) - labeled follows:

WASHDOWN PUMP: This 7.5 amp breaker supplies power to the optional raw water

washdown system (Option 284). The washdown option includes a 12 volt DC pressure water pump and all necessary fittings located at the transom and on the foredeck anchor locker.

WASTE PUMP: This 10 amp breaker controls the 12 volt pump used to empty the contents of the waste holding tanks on boats equipped with the overboard discharge system (Option 163).

FUEL TRANSFER PUMP: On boats equipped with diesel engines, a fuel transfer pump is used to equalize the volume of fuel between the two tanks. To transfer fuel, turn this 15 amp breaker to the ON position. The fuel transfer pump with 3-way switch and ON/OFF control is located in the cockpit panel below the helm.

SPARE: This 10 amp breaker has been installed for customer installed equipment

FWD & AFT SHOWER SUMP: The shower drain sumps on the 440 EXPRESS are installed below the water line. The pumps which drain the shower sumps are controlled by the two 2.5 amp breaker. The sump pump is activated by a float switch which engages at a specified water level and discharges the water overboard or into a waste holding tank.12 VOLT ELECTRICAL SYSTEM

PRESSURE WATER PUMP: The boat's fresh water system utilizes a pressure pump. When the 7.5A breaker labeled PRESSURE WATER is turned on, the pump will operate when the pressure within the water system falls below a specified level. Do not operate the pressure water pump when the fresh water tank is empty.

EXTERIOR ACCESSORIES circuit group (center) - Labeled as follows:

SYNCHRONIZER: This 10 amp breaker controls power to the engine synchronizer. This breaker must be turned on for the synchronizer to function.

HIGH WATER ALARM: This 5 amp breaker supplies power to an alarm connected to a high water float switch in each of your boat's bilge compartments. An alarm at the helm will sound in case of a bilge pump malfunction. If the alarm sounds, ascertain which bilge compartment is flooded and turn on the manual bilge pump switch for that compartment. Remember to turn your bilge pumps off when the water has been removed. Have your bilge pumps serviced immediately.

FWD HEAD FAN: A ventilation fan is installed in the head compartment of the boat. This 7.5 amp breaker controls power to the fan. A switch in the head turns the fan on or off as needed.

AFT HEAD FAN: A ventilation fan is installed in the head compartment of the boat. This 7.5 amp breaker controls power to the fan. A switch in the head turns the fan on or off as needed.

SPARE: These three breakers labeled SPARE have been installed in this group for owner installed equipment. The upper breaker has been rated at 15 amps, the middle breaker at 20 amps, and the lower breaker at 5amps.

EXHAUST FANS circuit group (bottom, aft)

BILGE BLOWERS: These breakers control power to the three bilge blowers. The upper breaker controls the bilge blowers in the engine room. The lower breaker controls power to the bilge blower in the lazarette. The blowers can be turned on or off at the helm station.

4.2.2 REMOTE CIRCUIT BREAKER PANEL

A drawing of the remote helm breaker panel appears on page 9 of this section. To aid the customer, the relative position of each circuit group on the panel has been noted after the group headings below.

MAIN circuit group (top, middle)

The top MAIN breaker must be on for any 12 volt circuit breaker on the boat to function. A subordinate main breaker has been installed on the salon 12 volt panel. This breaker on the remote panel must be switched ON for the salon MAIN breaker to function.

The upper MAIN circuit breaker controls the VOL TMETER, AUTO BILGE PUMP, FUEL TRANSFER, and BATTERY CHARGER circuit groups, along with the spring-actuated DAVIT, HATCH LIFT, and WINDLASS circuit breakers.

The lower MAIN circuit breaker controls the ELECTRONICS, and MANUAL BILGE PUMP circuit breaker groups.

VOLTMETER circuit group (top, port)

The two circuit breakers in this section control power to the voltmeter selector switch. The voltmeter reads the charge level in each engine battery bank.

AUTO BILGE PUMP circuit group (upper middle, port)

The 440 EXPRESS has four bilge pumps, one in each bilge compartment, and one in the lazarette. Each pump is controlled by a separate 7.5A breaker. Bilge pump control switches are located at the helm control station. Bilge pump operation is indicated by four individual indicator lights on the LED display on the 12V DC distribution panel.

These four circuit breakers control power to the automatic bilge pump circuits. These breakers are always ON for automatic pump activation when bilge water rises to a specified level. The bilge pumps are hard wired to the battery so they will automatically operate if activated by their float switch. Periodically test the float switches by lifting the floats to manually activate the bilge pumps.

The automatic bilge breakers are to be turned off for servicing the electric bilge pumps. The battery charger must also be turned off at the AC panel.

MANUAL BILGE PUMP circuit group (lower middle, port)

These breakers can be used for manual control of the boat's four bilge pumps. When activated by these circuits, the bilge pumps will not turn off automatically. DO NOT FORGET TO TURN THEM OFF AFTER THE WATER HAS BEEN REMOVED. ALLOWING A BILGE PUMP TO RUN DRY CAN CAUSE SERIOUS DAMAGE TO THE BILGE PUMP.

HOUSE circuit group (bottom, port) - labeled as follows:

CO DETECTOR: This breaker activates the circuit for the CO detectors. CO detectors are located in the forward stateroom, salon and aft stateroom. With the breaker on, if carbon monoxide is detected in any of these areas, an alarm will sound.

! DANGER!

ALWAYS activate the CO Detector when passengers are onboard and especially when the boat's engines and/or generator are running. Operating the air conditioner may create low pressure within your boat and this condition may draw exhaust in from other nearby boats. Carbon monoxide is a dangerous gas that is potentially lethal if inhaled. Refer to Section 2.3 for more information regarding carbon monoxide.

REMOTE LIGHTS: Turning this breaker on will allow you to activate your boat's exterior lights by remote control.

FUEL TRANSFER circuit (top, starboard)

This circuit controls the fuel transfer pump available with diesel engines only. To operate the pump, flip the switch toward the tank which you want filled. Fuel will be pumped from the opposite tank into the designated tank.

BATTERY CHARGER circuit group (middle, starboard)

NOTE: The breakers in this group control the flow of electrical current from the battery charger to the three batteries on your boat. The circuits controlled by these breakers will not function unless the BATTERY CHARGER circuit breaker is turned on at the helm AC panel. In addition, the cockpit accessory switch on the 120V panel must be on to energize the helm panel.

These circuit breakers supply power from the battery charger to the batteries. Flipping the top breaker charges the battery for the port engine. The middle breaker in this group charges the starboard engines battery. The lower breaker charges the battery for the generator

ELECTRONICS circuit group (middle, starboard) - Labeled as follows:

RADAR: If your boat is equipped with an optional, factory-installed radar unit, this 15 amp breaker labeled RADAR supplies power to the unit.

PLOTTER: If your boat is equipped with an optional, factory-installed plotter, this 5 amp breaker labeled PLOTTER controls electrical power to the unit.

VHF: This 10 amp breaker is provided to supply power to a factory installed or owner equipped VHF radio. GLOBAL POSITIONING SYSTEM: This 5 amp breaker can be used to power a Global Positioning System. The factory will install this system on your boat as part of the navigation package option.

DEPTH SOUNDER: If your boat is equipped with an optional depth sounder, this 2.5 amp breaker can be used for the power supply.

SPARE (2): These two breakers have been installed for dealer or owner-installed equipment. The top breaker is rated at 5 amps. The lower breaker is rated at 10 amps.

MISCELLANEOUS circuits

In addition, there are three circuit breakers below the main circuit breakers on the remote panel. These circuit breakers can only be used to reset the circuit if a breaker is tripped.

The DAVIT circuit breaker protects the circuit for the optional davit for the personal watercraft in the lazarette. A 12' remote control cable is supplied to control the davit.

The HATCH circuit breaker protects the circuit for the lazarette hatch lift. The switch for the hatch lift is on the starboard side of the cockpit area, at the aft end of the wet bar.

The WINDLASS circuit breaker protects the circuit for the windlass motor. The remote switch is at the helm console. Additional foot switches are located in the deck at the bow of the yacht.

4.3 BATTERY INSTALLATION

4.3.1 Gasoline engines

The direct current, or DC, electrical system is powered by two D-8 cold cranking amp deep cycle batteries.

A third deep cycle 12V battery is used for starting and operating the generator and is recharged automatically when the generator is operated. Power from this battery to the generator is controlled by an ON/OFF switch installed near the generator.

Your boat's batteries are located on the centerline of the bilge compartment between the engines.

4.3.2 Diesel Engines

Each diesel engine utilizes the starting power of a 300 Amp deep cycle battery. Two batteries are available to start the engines. A third deep cycle 12V battery is used for starting the generator and is recharged automatically whenever the generator is operated. Power from this battery to the generator is controlled by an ON/OFF switch installed near the generator.

12 VOLT ELECTRICAL SYSTEMS

4.4 12V WIRE STANDARD

4.5 12V TROUBLE SHOOTING

-------------------------------------------------------------

Section 5 - AC Electrical Systems

5.1 Using the AC System

5.1.1 Introduction

5.1.2 Reverse Polarity

5.1.3 Salon AC Panel

5.1.4 Remote AC Panel

5.1.5 Selecting a Power Source

5.1.6 50A Main Breaker

5.1.7 Connecting to Shore Power

5.1.8 Using the Onboard Generator

5.1.9 Dual Dockside Service

5.2 AC Electrical Equipment

5.2.1 Ground Fault Interrupters

5.2.2 Electrical Loads

5.2.3 Salon AC Circuit Breaker Panel

5.2.4 Remote AC Circuit Breaker Panel

5.3 AC Generator

5.4 Air Conditioning System

5.5 Stray Current and Galvanic Corrosion

5.5.1 Stray Current

5.5.2 Galvanic Corrosion

5.6 Bonding System

5.7 AC Trouble Shooting

5.1 AC ELECTRICAL SYSTEM

5.1.1 INTRODUCTION

The 50 amp AC electrical system is powered through the use of a dockside power source or by an onboard generator. The lower MAIN breaker in the bottom middle of your AC panel controls the circuits used for single dockside wiring. The MAIN breaker in the upper half of the panel controls the circuits used for dual dockside wiring. Dual dockside service is installed if your boat is factory equipped with air conditioning. Dual dockside service is explained in section 5.1.6. The shore power or dockside electrical system of your 440 EXPRESS uses three wire, color-coded circuitry. The black wire in a circuit carries the current from the power source to the outlet. Each black wire is connected to and protected by a circuit breaker that is

installed in the circuit breaker panel. The white wire carries the current from the outlet back to the power source. Ground wires will be either green or bare copper wires. Current does not usually flow through the ground wires. Buss bars are used within the electrical system to help route and organize the wires. The system's white or neutral wires are connected together at buss bars. The ground wires are also connected together at another independent buss bar.

!DANGER!

The black and white wires are hot, current carrying wires. Do not touch them while the system is connected to a power source.

5.1.2 REVERSE POLARITY

Reverse polarity only occurs with 11 OV electrical systems. If your boat is equipped with a

220V system, disregard this section. The MAIN circuit within your boat's electrical system is designed with a circuit that senses incorrect flow between the neutral and positive. If the dockside electrical power source is incorrectly wired and the polarity is reversed, the red reverse polarity light in the dockside electrical box will come on. If reverse polarity occurs while your boat is connected to shore power, the reverse polarity light on your boat's AC electrical panel will come on.

!WARNING!

If reverse polarity occurs, turn off the 50A main breaker(s) on your AC electrical panel and disconnect your power cord(s) from the shore power supply. Notify marina management of the problem. Use a different dockside electrical box.

5.1.3 AC ELECTRICAL PANEL